Customer Success Stories

Explore how PRIZM is being used in real-world applications to solve complex problems and drive innovation. Here are some examples of successful implementations.

Case study 1: Industrial cleaning equipment manufacturer

A major manufacturer and rental provider of indoor and outdoor industrial floor cleaning equipment.

The challenge

Battery overheating and charging misuse created serious safety risks across a nationwide fleet. The team needed remote battery monitoring to track charging history, temperature, and usage patterns, with alerts for abnormal behavior, without redesigning machines.

Why they chose PRIZM by Nextwave

They wanted a practical retrofit that could be deployed fast and repeated across many units. PRIZM stood out for fast setup and the ability to configure dashboards and alerts without custom development.

What changed

PRIZM gateways and sensors were attached directly to the batteries and hardware setup was completed in a single day. An on site engineer used PRIZM’s no code App Builder to configure dashboards, thresholds, and monitoring rules.

The results

They moved from blind spots to 24/7 visibility and early alerts for overheating and improper charging. The pilot performed beyond expectations and the team is now discussing embedding PRIZM as a standard feature across rental equipment and new sales, with connected safety as a differentiator.

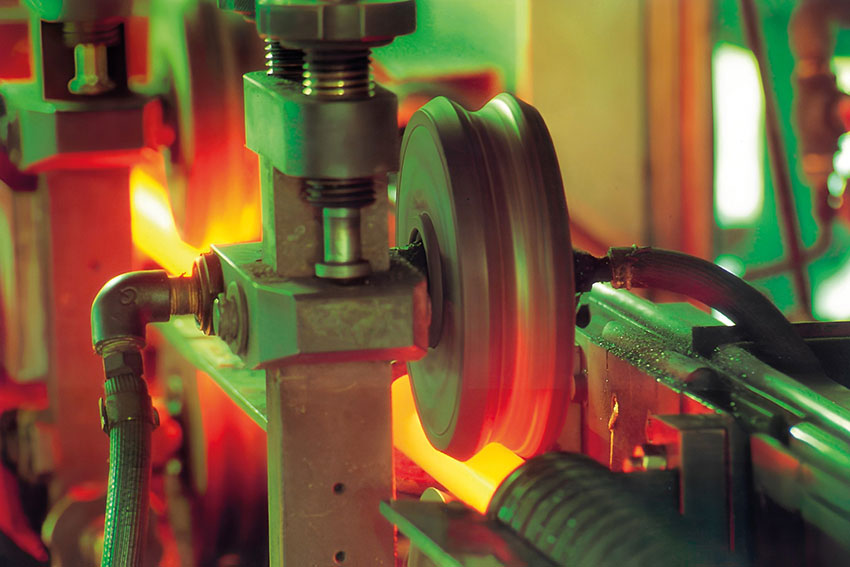

Case study 2: Industrial induction heating equipment manufacturer

A global leader in high frequency industrial induction heating machinery.

The challenge

Failures in critical consumables caused costly downtime. Because their legacy machines weren’t connected, engineers lacked the operating data needed to diagnose issues early, reduce downtime, and improve future designs.

Why they chose PRIZM by Nextwave

They needed a non-invasive way to connect legacy PLC data and start building a predictive maintenance workflow without modifying machines.

What changed

Using PRIZM’s plug and play gateway, the team accessed existing PLC data and sent it to the cloud. PRIZM began collecting key signals such as temperature, cycle counts, and flow rates, creating a consistent data layer they can use across sites.

The results

The team gained remote visibility into equipment health and a realistic path toward predictive alerts and maintenance planning. With PRIZM’s global cellular connectivity, the deployment is positioned to scale across worldwide legacy units without new infrastructure.

Case Study 3: Industrial rubber and thin film product manufacturer

A manufacturer producing industrial rubber and thin film products on high value equipment.

The challenge

Unexplained vibrations and shocks were increasing defects. The team could not pinpoint when events happened, what triggered them, or how to connect them to specific machine conditions.

Why they chose PRIZM by Nextwave

They needed fast instrumentation without altering equipment, plus immediate access to usable vibration data for engineering analysis.

What changed

In under a day, PRIZM gateways and vibration sensors were installed with no machine modifications. Data streams became available immediately, allowing engineers to analyze patterns and correlate vibration behavior with gearbox related issues.

The results

They identified root causes and reduced defects by moving from guesswork to evidence. The speed of deployment helped build internal confidence and the customer later launched additional projects using PRIZM monitoring and analytics. The relationship also deepened beyond a single pilot.

Case Study 4: Healthcare device developer

An AI focused team building radar based senior monitoring devices for fall detection, sleep tracking, and vital sign monitoring.

The challenge

They needed to validate models and sensor integration quickly, but building the IoT stack internally required too much time, expertise, and cost. Data pipelines and devices to cloud connectivity were slowing product learning cycles.

Why they chose PRIZM by Nextwave

They wanted a faster way to connect sensors, move data to the cloud, and iterate, without becoming an IoT engineering team.

What changed

Using the PRIZM Development Kit, they integrated radar sensors and validated AI models in a few days, then moved toward embedding PRIZM into the final hardware to support reliable device connectivity with their proprietary cloud platform.

The results

They accelerated prototyping and model validation, reduced engineering burden, and created a scalable foundation for connected devices so the team could focus on the product and the algorithms.

Bring intelligence to your operations

Start collecting data from your machines today.

PRIZM

PRIZM connects any machine, device, or sensor and turns raw signals into structured data you can use for monitoring, automation, or AI.

- Hardware

- Connectivity Card

- Gateway